Our History - Akrylmetal

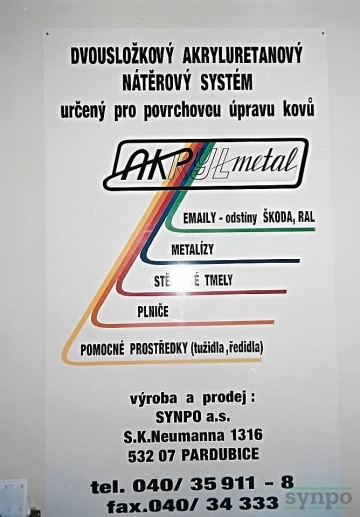

Our long-standing flagship product was developed at the turn of the 1980s and 1990s as a highly advanced coating system model with tinting capabilities, designed for automotive refinishing and a variety of industrial applications. With its well-thought-out structure, which includes primers, fillers, enamels, two-layer metallic coatings (base coat and clear coat), and putties – mostly in the form of two-component polyurethanes – it clearly filled a gap in the coatings market. Because the production was on a smaller scale, it was possible to provide customers with above-standard services such as custom color matching of aged paint. Although this service is now standard, at the time of Akrylmetal's inception, it was quite unique.

Component A, or the polyol, was formulated based on the Veropal D133 resin, which was developed directly at Synpo. Before 1989, this was a way to save foreign currency, although it was not possible to reduce costs for the hardeners, which were based on polyisocyanates. The system therefore completely relied on hardeners produced by Bayer. Today, we are able to optimize the properties of each system element using binders from abroad, and polyols are now combined in various ways in products. The hardeners have also had to evolve, particularly due to legislative pressure. Currently, all products contain less than 0.1% of monomeric isocyanates, which allows them to be sold to consumers without restrictions and spares professional and industrial customers the administrative burdens resulting from newly introduced regulations.

The concept of pigment pastes, on which the enamels were built, still persists today. It offers an elegant way to easily tint colors, either based on color charts (such as RAL standards or car manufacturer palettes) or by using a colorimeter to measure shades. Although tinting is now made easier with the help of computer technology, the human eye – which has played a key role from the beginning – still hasn’t been fully replaced. For more demanding applications, freshly mixed material is checked and fine-tuned by an experienced technician. The goal of this process is to achieve minimal color deviation, calculated from color coordinates, which in the automotive industry is usually less than 1 – making it indistinguishable to the untrained eye. Tinting aged car paints wouldn't be possible without small portable devices. In this field, we rely entirely on the company X-Rite.

From the beginning, production was performed using a continuous pearl mill, which we still rely on today. We remain loyal to the brand Willy A. Bachofen AG and their model line Dyno-Mill. These machines are very well constructed, with minimal failure rates and high production capacity.

Promotion of the product line once again relied on human ingenuity. Preparing color charts was always a labor-intensive task, and adapting to global standards – such as the RAL system – was only possible thanks to the inventiveness of the Czech people. Market success was also driven by extensive technical support, which addressed application challenges and gradually adapted the system for substrates other than metal. The current product range even includes nano-coatings with special properties and an anti-graffiti line.

Applications in the 1990s often had an extravagant flair (see photo), whereas today we tend to blend in with the crowd of competing products. However, our key advantages remain: the ability to tailor product properties precisely to customer needs, excellent technical support, and high flexibility in both execution and volume.