SERVICES AND PRODUCTS > BROOKFIELD INSTRUMENTS > INSTRUMENT SELECTION

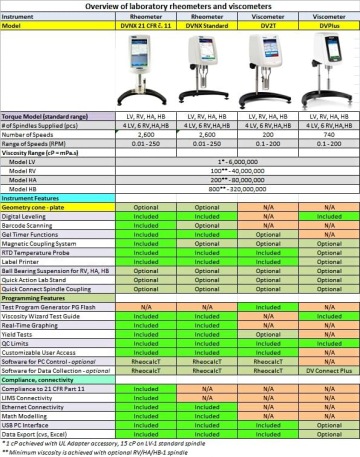

Instrument Selection

Looking for a lab instrument, but not sure which one? Synpo is ready to help you make the correct choice for your application. Just call or email us for an immediate discussion about your requirements.

There may be industry or supplier/vendor specifications that you need to follow. Before making a final selection, we suggest that you confer with people in your industry to find out which Brookfield viscometer they are using so that your data can be correlated.

Brookfield viscometers/rheometers are supplied with a standard spindle set constructed of stainless steel (#302), however, other options such as #316 stainless steel, cylindrical, vane or Teflon coated spindles for increased corrosion resistance are also offered.

LAB Units QUESTIONS

- What is the viscosity range of your material: Low (1-10,000 cP), medium (500-500 000 cP), high (5,000-2 000 000 cP)?

- What rotational speeds or shear rates are important?

- How much sample is available for testing? Small (<500 ml) or large (>500 ml)?

PROCESS Units QUESTIONS

- What is the viscosity range of your material?

- Is your material Newtonian, dilatant, non-Newtonian, thixotropic or pseudoplastic?

- What is the minimum, maximum and average pressure requirement of your application?

-

What is the minimum, maximum and average temperature of your application?

-

What is the minimum, maximum and average flow rate of your application?

-

Where in production would you like to have the viscometer: in-line, on the top of the tank or on the side of the tank?

-

What electrical code requirements do you have:

- NEMA 1 (general purpose-indoor)

- NEMA 4 (watertight/dust tight for indoor/outdoor use)

- NEMA 7 (explosion proof-Class 1, Div. 1&2, Group D)

- ATEX (explosion proof-Code: EE x d 11B T6)