We are able to determine free Bisphenol A in solid epoxides

Epoxy resins can be found almost everywhere – in coatings, adhesives, flooring, electronics, and protective layers for packaging. During their production, a substance called Bisphenol A (BPA) is used. Ideally, BPA should be “chemically bound” within the polymer structure in the final material. However, small amounts may sometimes remain free (unreacted). That is exactly what needs to be monitored.

Why is this important?

BPA has been closely monitored for a long time because it can affect the human hormonal system. For this reason, its content is regulated – especially in materials that may come into contact with food (for example, under regulations of the European Union).

Monitoring free BPA helps ensure that:

- products are safe,

- manufacturers comply with legal limits,

- the production process has been carried out correctly.

How is BPA determined?

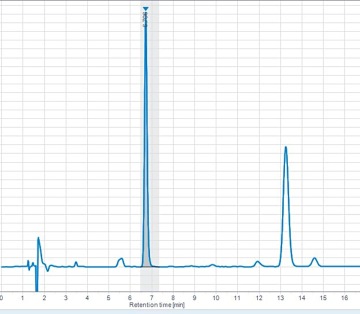

A laboratory method with a rather long name is used: High-performance liquid chromatography, abbreviated as HPLC. In practice, it can be imagined quite simply. HPLC works similarly to a highly precise filter or “sorting device” for molecules.

- The epoxy resin is first dissolved in a suitable solvent.

- The solution is introduced into the instrument.

- Inside the system, the individual substances are gradually separated.

- The instrument detects when BPA elutes and measures its amount.

The result is a numerical value – for example, how many milligrams of BPA are present in one kilogram of material.

Why is it somewhat complicated?

Epoxy resin is a solid and highly resistant material. Moreover, BPA is usually present only in very small amounts. Therefore, the laboratory must:

- dissolve the resin properly,

- use an appropriate solvent,

- ensure that only free BPA is measured.

The entire procedure must be carefully validated to ensure reliable results.

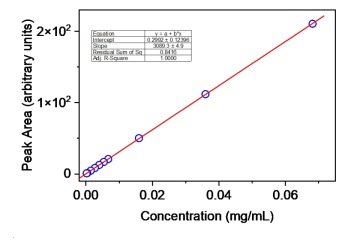

How precise is it?

Modern instruments can detect extremely low concentrations – down to a few thousandths of a milligram of BPA per kilogram of epoxy resin. In some cases, even more sensitive variants of the method are used (for example, with mass spectrometric detection), but standard HPLC is usually sufficient for routine quality control.

What does this mean for the general public?

For consumers, the key points are:

- manufacturers are required to monitor BPA content,

- precise laboratory methods exist,

- results are measurable and verifiable.

Determining free BPA is therefore not just “academic chemistry,” but a practical tool to ensure the safety of products around us.

Simple summary

Free BPA = a small amount of unreacted substance in epoxy resin used to manufacture various products.

HPLC = a highly precise laboratory method capable of detecting and measuring it.

Goal = safety, quality, and compliance with legal requirements.