We monitor mechanical tests using modern optical technology

When people hear the term mechanical properties, most think of tensile tests, bending, hardness, or impact toughness. However, few realize that modern optical technologies now play a major role in these tests. One of the most widely used and reliable instruments in this field is the ATOS Core 200, a precise 3D optical scanner that significantly improves and speeds up the evaluation of material behavior under load.

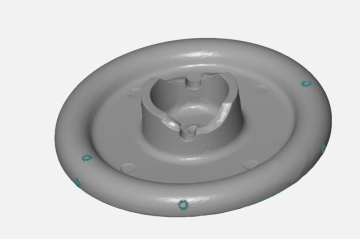

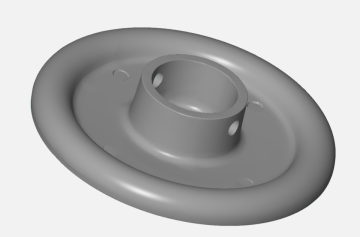

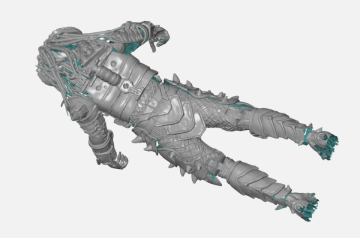

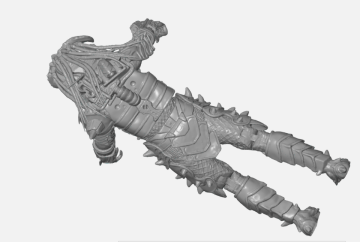

We use this device for evaluating mechanical properties and for 3D scanning. ATOS Core 200 is a safe optical 3D measurement system that uses structured blue light to capture the shape of objects with high precision. The output is a detailed 3D model — essentially a digital copy of the specimen that captures even very fine deformations. This makes it invaluable for mechanical tests where it is necessary to monitor changes in the specimen’s shape and surface during or after loading.

Applications in Mechanical Testing

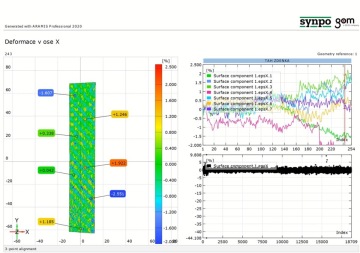

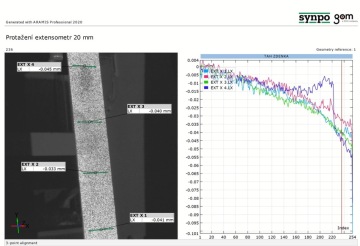

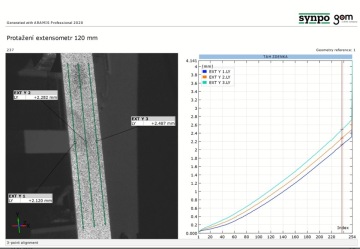

- Monitoring deformations

- The device can be used to measure changes in the shape of a specimen during loading.

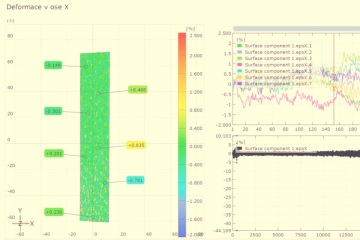

- Digital Image Correlation (DIC)

- In combination with GOM Correlate software, it enables real-time tracking of displacements and surface deformations.

- Non-contact measurement

- It allows measurements without influencing the specimen, which is crucial in mechanical property testing.

Applications in 3D Scanning

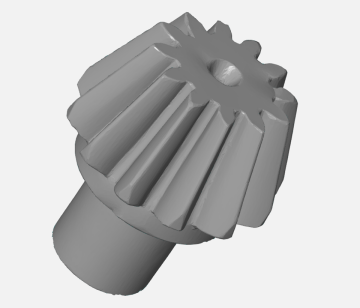

- Digitalization of complex-shaped parts

- Suitable for technical components, plastic moldings, and metal parts.

- Quality control

- Comparing the scanned model with CAD data and detecting deviations.

- Reverse engineering

- Creating a digital model for further modifications or production.

- Advantages over tactile probes

- It captures entire surface areas at once rather than individual points.

Description of the GOM – ATOS Core 200 System

- 2 cameras with 5 MPx resolution

- Scanning speed: 7 Hz

- Measuring volume: 200 mm × 150 mm

- Measuring distance: 250 mm

- Point spacing: 0.08 mm

- Sensor dimensions: 206 mm × 205 mm × 64 mm

- Weight: 2.1 kg

- Calibration object with calibration certificate

- Acceptance test performed by GOM using a reference object with precision-ground spheres according to VDI 2634 Part 3

- Acceptance protocol with certificate for the master reference standard

- Output formats: G3D, STL, POL, PLY

How ATOS Core 200 Supports Mechanical Testing

1. Monitoring Deformations During Testing

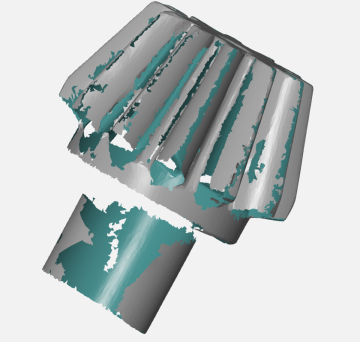

During tensile, compressive, or bending tests, the specimen gradually changes — it elongates, narrows, or fractures. The ATOS Core 200 can capture these changes with micrometer-level precision and display them as color-coded deformation maps.

2. Fracture and Defect Analysis

After impact tests or specimen failure, the scanner can capture the fracture surface. ATOS Core 200 can reveal fine structures and surface irregularities that indicate:

- whether the fracture was brittle or ductile

- the location of the initial crack

- whether the material is homogeneous or shows hidden defects

This information is crucial for assessing the reliability and integrity of the material.

3. Measuring Material Loss and Wear

During cyclic tests, such as fatigue testing, the device can also be used to evaluate material wear. By scanning the specimen before and after loading, you can obtain quantitative data on material loss or shape changes.

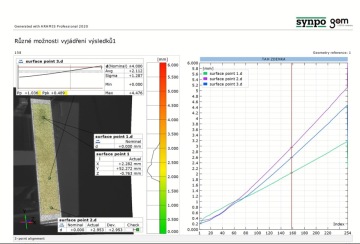

4. Comparison with Simulation Models

Numerical simulations (e.g., FEM) are a standard part of modern development. To ensure accuracy, simulations must be validated against real-world data.

ATOS Core 200 allows comparison between:

- calculated deformations

- actual measured values

This enables simulations to be refined and their predictive accuracy improved.